About DESS Dental Smart Solutions

DESS Dental Smart Solutions is a prosthetic solutions provider that offers compatible abutments with the most popular brands in the market. With more than 30 compatibilities and more than 2000 references, DESS® has the most comprehensive range available in the market and most certainly your best alternative when it comes to finding the best supplier for your dental prosthetic needs.

The conception of our products is based on the "Pure Switch" philosophy, which means all our products can seamlessly be used to replace the originals. This concept gives the professional a great deal of flexibility, as he can use both the original product and the DESS® product without losing any of its features. Following this idea, the backbone of the "Pure Switch" concept is our screw, as it is identical to the original and perfectly interchangeable.

The "Pure Switch" responds to the need to create a prosthetic solution that can fully replace the original without compromising the quality or strength of the product. All our abutments are tested to guarantee their correct functioning.

Due to our high-quality standards, we trust in everything we manufacture. For this reason, we have a full warranty on all our products, both single and in combination with third party implants. DESS® offers a lifetime replacement warranty on all abutments, even those used with any claimed compatible dental implant, also covering immediate prosthetics with All-on-4 treatment or other cases with Multi-Unit.

AURUMBase®

DESS® take on angled screw channel

There are numerous clinical situations where the long-axis of the implant results in an unfavourable location of the prosthetic screw access hole. One solution might be to sacrifice the retrievability and cement over the access hole or compromise the aesthetic results.

There are numerous clinical situations where the long-axis of the implant results in an unfavourable location of the prosthetic screw access hole. One solution might be to sacrifice the retrievability and cement over the access hole or compromise the aesthetic results.

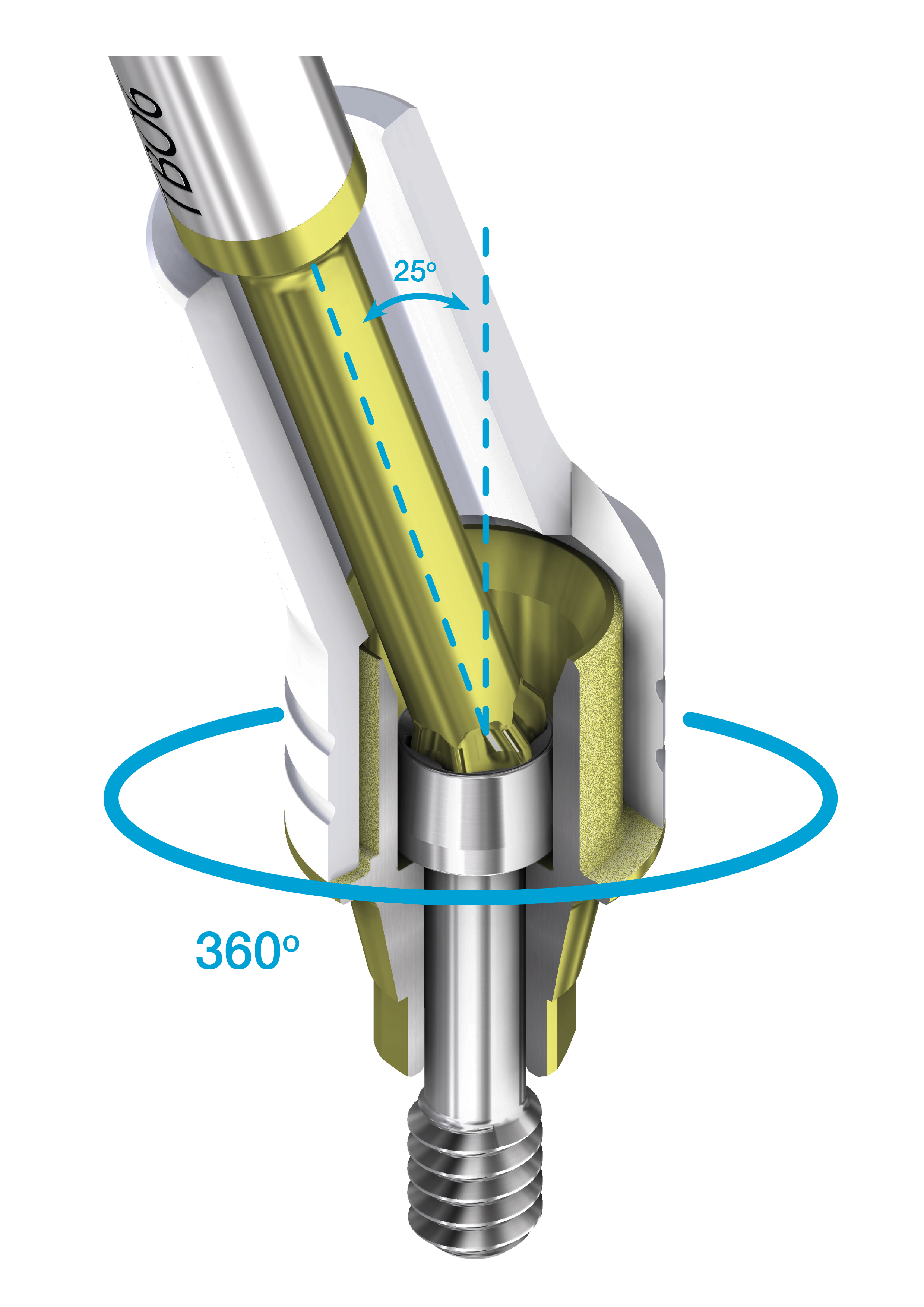

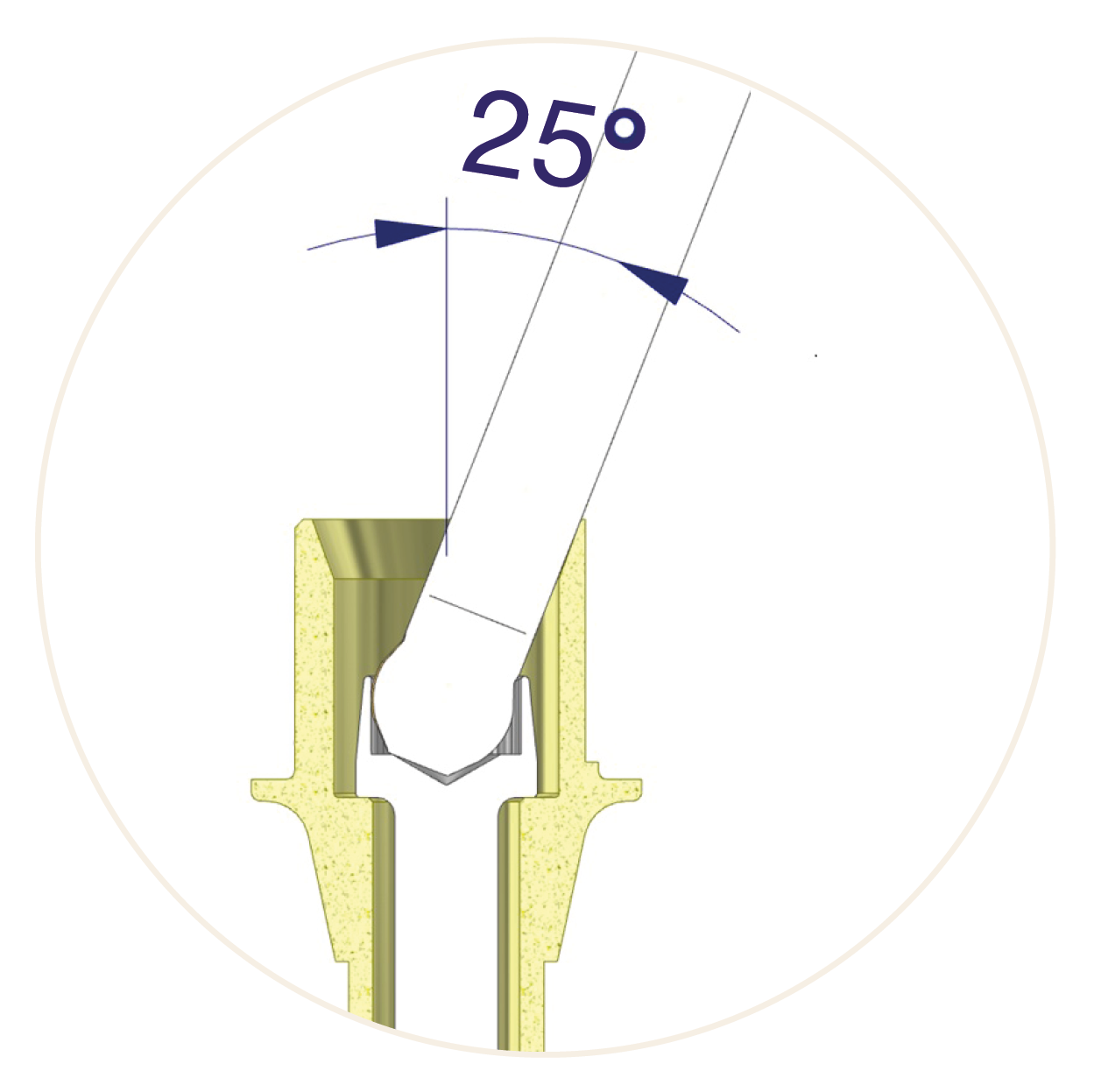

In 2018 DESS® introduced the AURUMBase® system which allows an angular adjustment of up to 25° on the screw access hole. The specially designed Torx®-based screw and driver concept will retain the ability to use full recommended torque even at full angulation.

The AURUMBase® is made of titanium grade V ELI and has a gold colour anodized surface finish that will further optimize the appearance especially in the aesthetic zone. The shaft also features the patented and well proven SelectGrip® surface treatment for optimal cement retention. To facilitate prosthetic work using traditional casting procedures AURUMBase® pre-formed castable caps can be used. They are delivered in multi-packs of 5 pieces, in a straight version as well as pre-angled with 10° and 20°. They are designed to optimize the placement and tightening of the AURUMBase® screw with the special Torx® driver.

Angular freedom

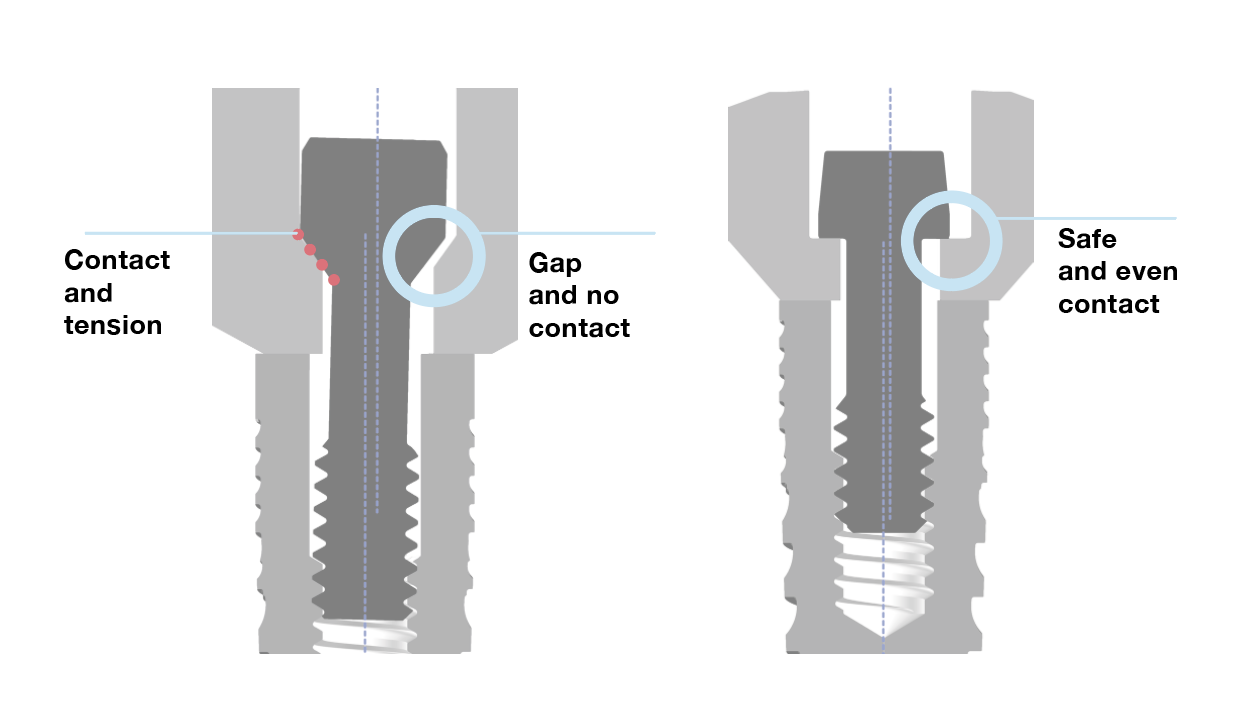

All AURUMBase® screws have a flat seat to minimize tension when there is a slight misalignment between screw retained structures and implants. A flat design is more forgiving and transfers the torque to an optimal preload of the screw. A conical screw requires a perfect alignment and centering between the screw and seat.

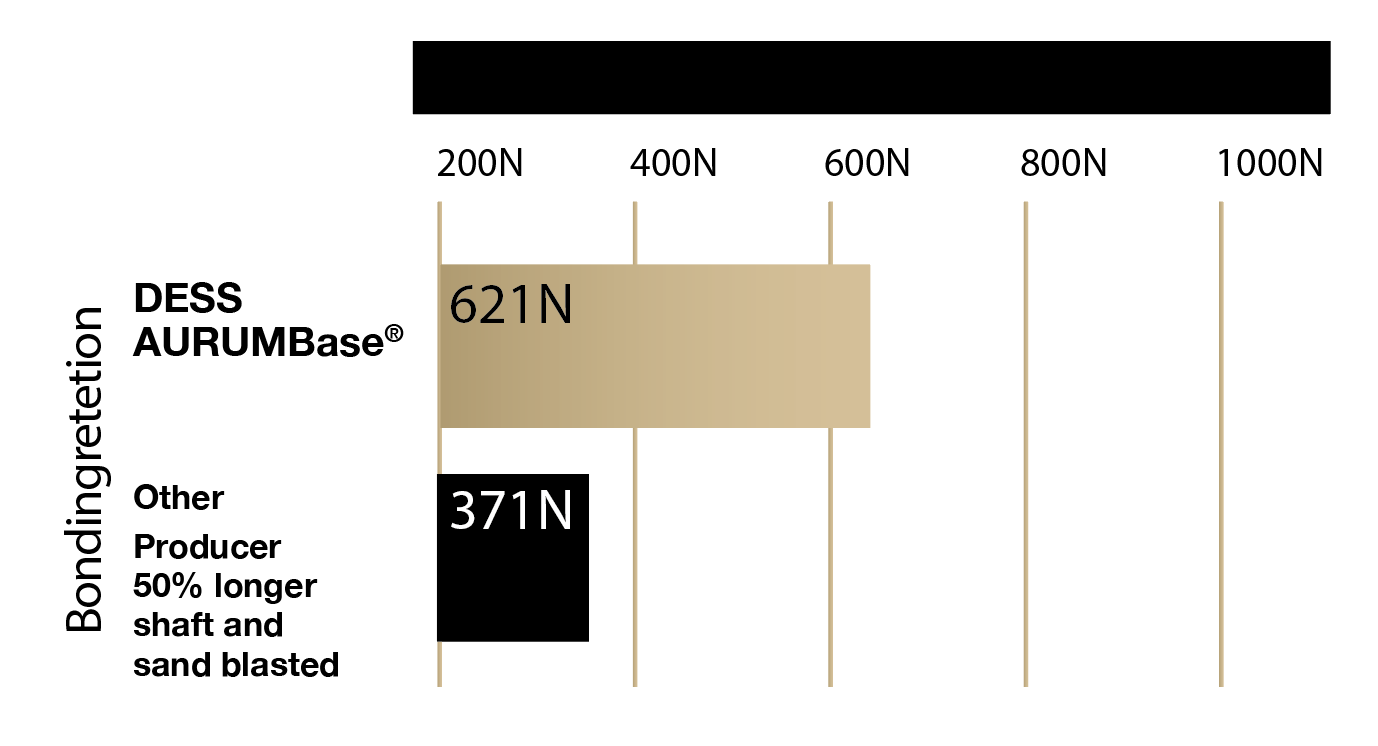

To optimize the possible angulation of the access hole the shaft of the AURUMBase® has been reduced to only 3mm, but with a bonding area of more than 33mm2, is bigger than other higher but sliced solutions. During the development we conducted both debonding and static fatigue tests comparing the results not only to the standard DESS® Ti-Base but also to competitors’ components. A dynamic fatigue test was also conducted and passed the required 5 million load cycles.

To optimize the possible angulation of the access hole the shaft of the AURUMBase® has been reduced to only 3mm, but with a bonding area of more than 33mm2, is bigger than other higher but sliced solutions. During the development we conducted both debonding and static fatigue tests comparing the results not only to the standard DESS® Ti-Base but also to competitors’ components. A dynamic fatigue test was also conducted and passed the required 5 million load cycles.

Compatibilities:

ElliptiBase®

The aesthetical solution for small restorations

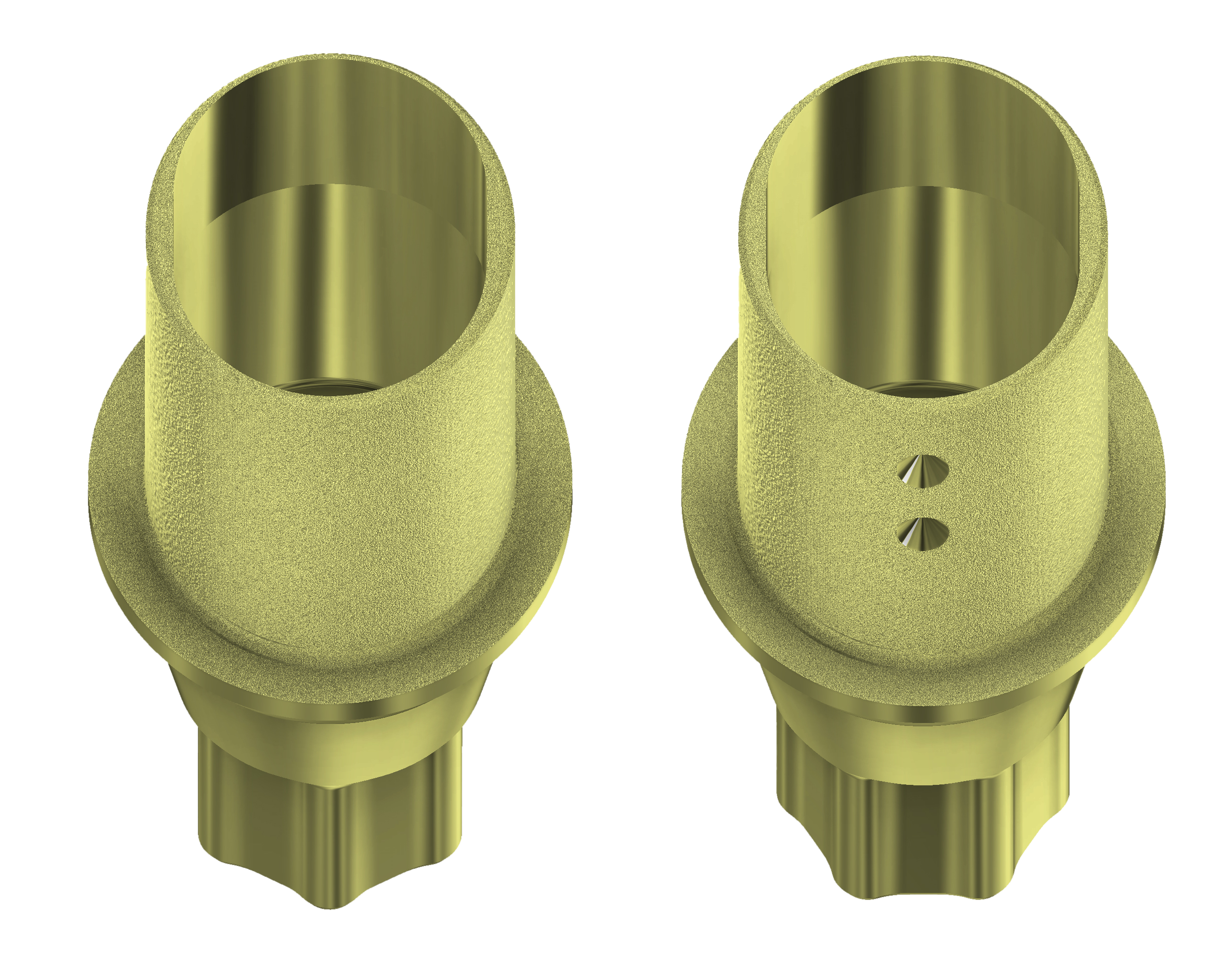

The ELLIPTIBase® has been conceived to achieve a better result on tight spaces. It has been specially designed to be used in cases where there is a small space between teeth, like the anterior teeth section. Up till now those clinical cases would present serious challenges with standard Ti-bases. Only available on small platforms (3.0 & 3.5), this innovative DESS® product can be acquired in two orientations of the shaft to the implant connection: flat and corner.

Its special elliptic and narrow design makes it the best prosthetic solution for cases with little spacing between pieces. Its design has been conceived to adapt to the geometry of the mouth.

The DESS® ELLIPTIBase® is made of Titanium Grade V ELI and SelectGrip® sandblast to ensure the optimal cement retention. This original solution from DESS Dental Smart Solutions is a demonstration of our commitment towards innovation and the pursuit of solutions that fit the clinical needs of our clients.

The DESS® ELLIPTIBase® is made of Titanium Grade V ELI and SelectGrip® sandblast to ensure the optimal cement retention. This original solution from DESS Dental Smart Solutions is a demonstration of our commitment towards innovation and the pursuit of solutions that fit the clinical needs of our clients.

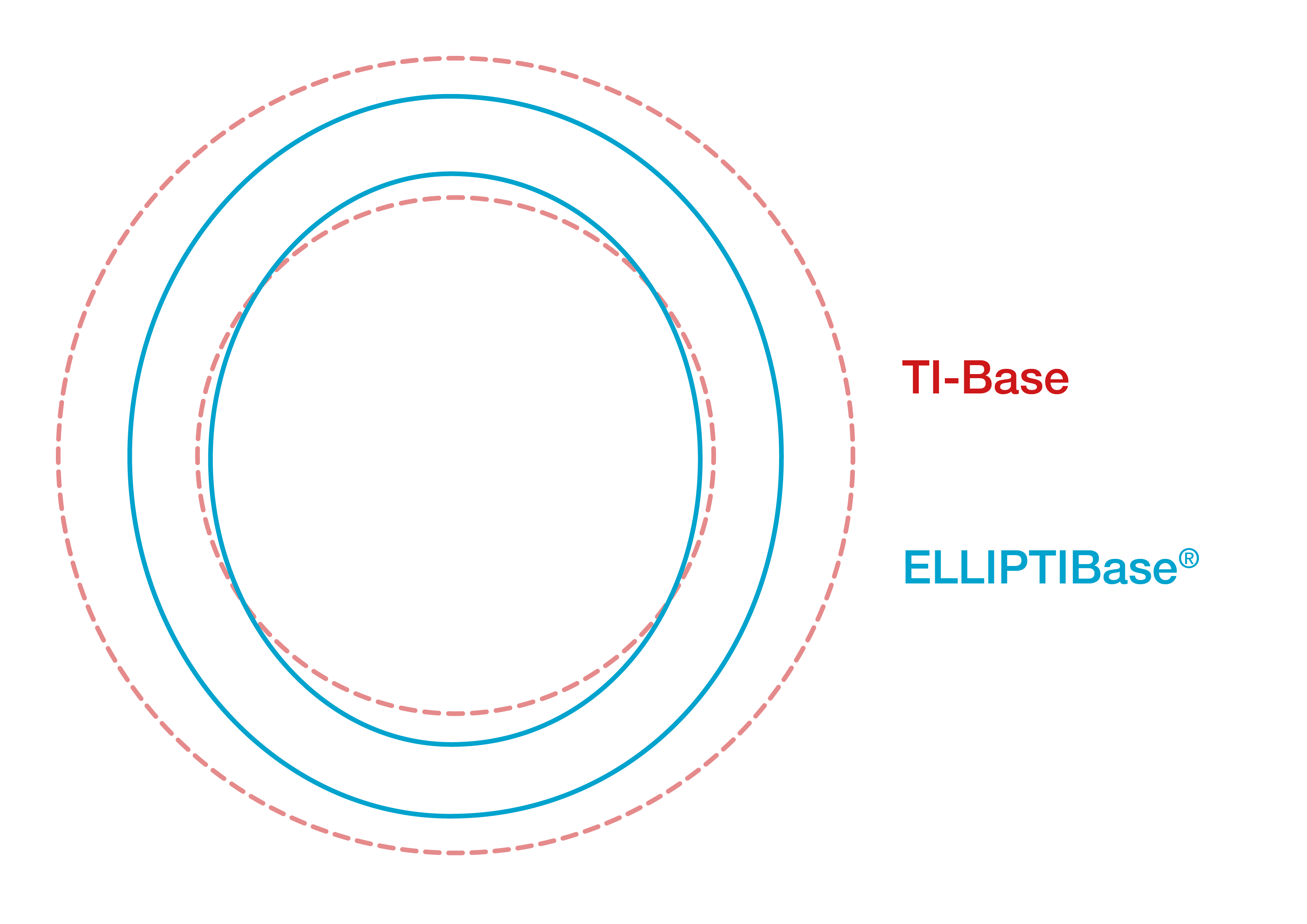

DESS® ELLIPTIBase® is narrower, allowing more space for the Zirconium. We have managed to reduce in a 22% the material, compared to our Ti-Base. As you can see in the image below, the ELLIPTIBase® is a slender version of a traditional Ti-Base, making it the perfect solution for clinical situations without space. It is compatible with the smallest platforms of the compatibilities shown below.

Compatibilities:

Multi-unit

Discover our transepithelials

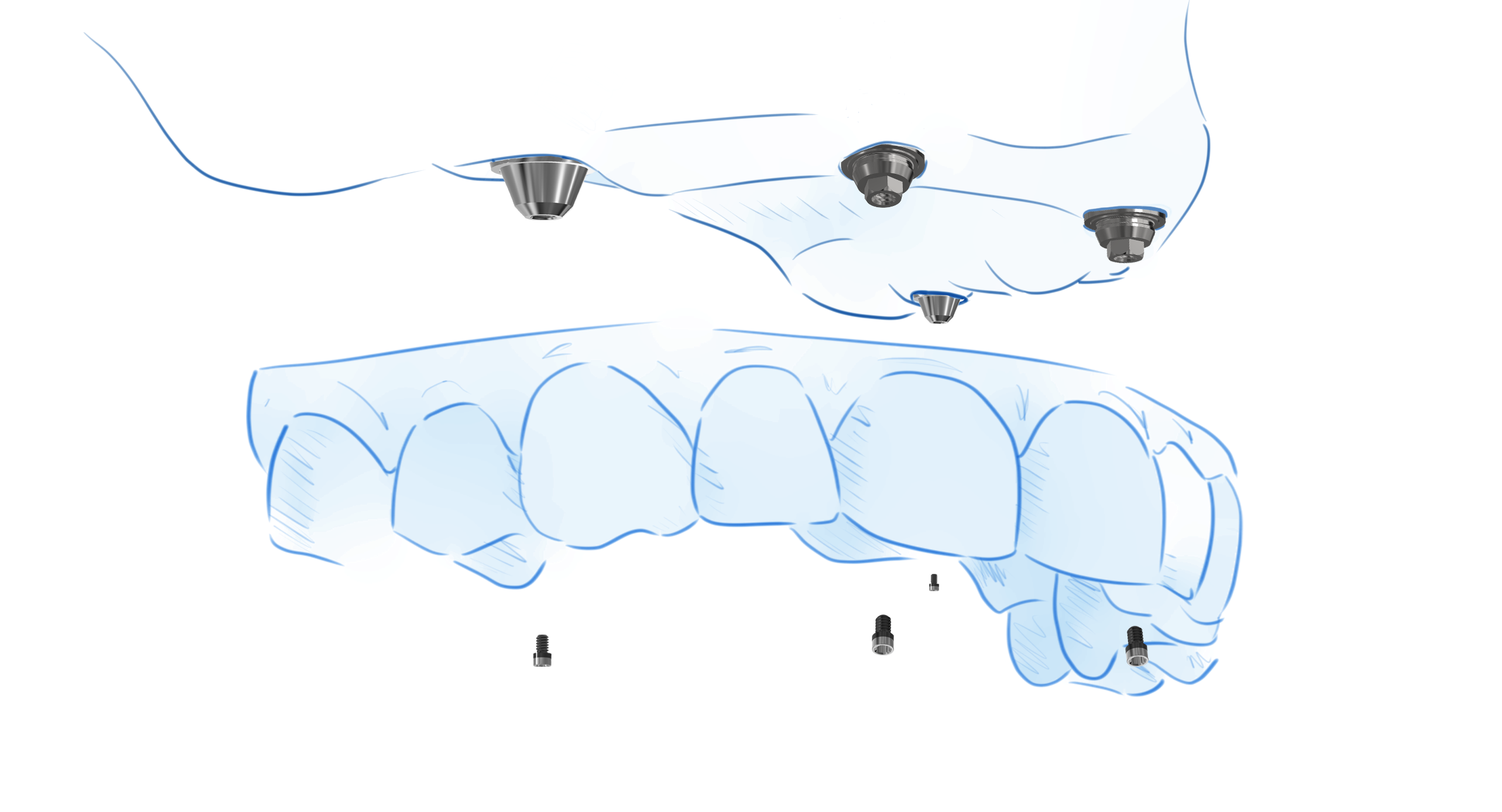

When it comes to full arch restoration the use of transepithelial abutments is one of the most successful and proven techniques. This type of solution reduce the amount of

implants needed for a full restoration, substantially reducing the cost, chair and heailing time. One of the key advantages is the standardization achieved with a unique prosthetic platform across the different implant compatibilities and with the standardized treatment protocol, achieving a very high rate of success. Main advantages:

- Full-arch rehab with four implants.

- Shorter treatment times.

- Correct insertion axis of the prothesis-implant connection.

- Different gingival heights to allow adjusting different implant depths.

- Graftless procedure.

At DESS® we offer the most comprehensive range of transepithelial abutments, including UniAbutments, converter abutments and Multi-units, also for implant platforms that lack these solutions as standard.

DESS® Multi-unit abutments are an excellent and simple solution for the construction of screw-retained prosthetic structures, both in full and partial restorations, in almost any clinical situation. These low-profile connections come with different insertion angles and various gingival heights for greater clinical adaptation and exceptional esthetic results.

TThey offer a powerful component-based protocol to standardize the required angle and level the prosthetic platform. By using these types of abutments that approach the angle of the seated implant and the depth of each placement site, optimal esthetics are enabled.

DESS® Multi-units are made of Titanium grade V ELI and are tested on strength and durability. In addition, some of them include a DLC covered screw, which through lower friction provides higher pre-load and optimal retention.

Straight and angled Multi-unit abutments

Straight Multi-unit Abutments are easy to use and offer screw-retained prosthodontic solutions for all clinical situations where implants with a divergence of up to 40° are used. Designed for an optimal fit between the abutment seat and the implant connection for all types implant connections.

Available in 17° and 30°, DESS® Multi-unit Angled Abutments are easy to use and the perfect solution when treatment angulation correction is needed.

You can find the free Multi-unit and UniAbutment libraries that will allow you to freely design structures for most CAD/CAM systems.

Ti-Base for Multi-unit

DESS philosophy is based on providing dental solutions for any clinical case. The contact we maintain with users allows us to know firsthand their needs and to be able to innovate in order to offer them solutions that adapt to their requirements.

That is why in 2019 we launched a new Ti-Base for Multi-unit, with more height, which gives us a larger cementation surface. You will find two heights in our catalogue:

- 6 mm

- 8 mm

Compatibilities:

DESSLoc®

The ultimate overdenture anchor

DESSLoc® abutments are used to support removable overdentures on implants. These types of abutments are a great solution to support a complete arch with just 2 implants and make the prothesis removable. Used in conjunction with flexible males the overdenture fits into the abutments by exerting slight pressure.

Benefits of DESSLoc® abutments:

- Low emergency profile

- Double retention

- Different levels of retention, color coded

To the already known advantages of the traditional components, DESS® has added some improvements that make DESSLoc the best solution for such restorations.

These improvements come mainly from the exclusive coating of Zirconia Nitride (ZrN), a fully biocompatible material which increases the hardness of the abutment surface.

Additionally, it decreases the coefficient of friction in comparison to the traditionally used Titanium Nitride and vastly out-performs some of the low-quality alternatives that have no coating or are simply anodized.

Thanks to the ZrN surface treatment a reduction of inflammation as well as a decrease in plaque formation is observed. Due to these increased performances the DESSLoc® abutment has an improved functional life in comparison to other solutions. Furthermore, the color of the coating increases the aesthetic quality of the prosthetic restorations.

100% compatible with Locator® Abutments.

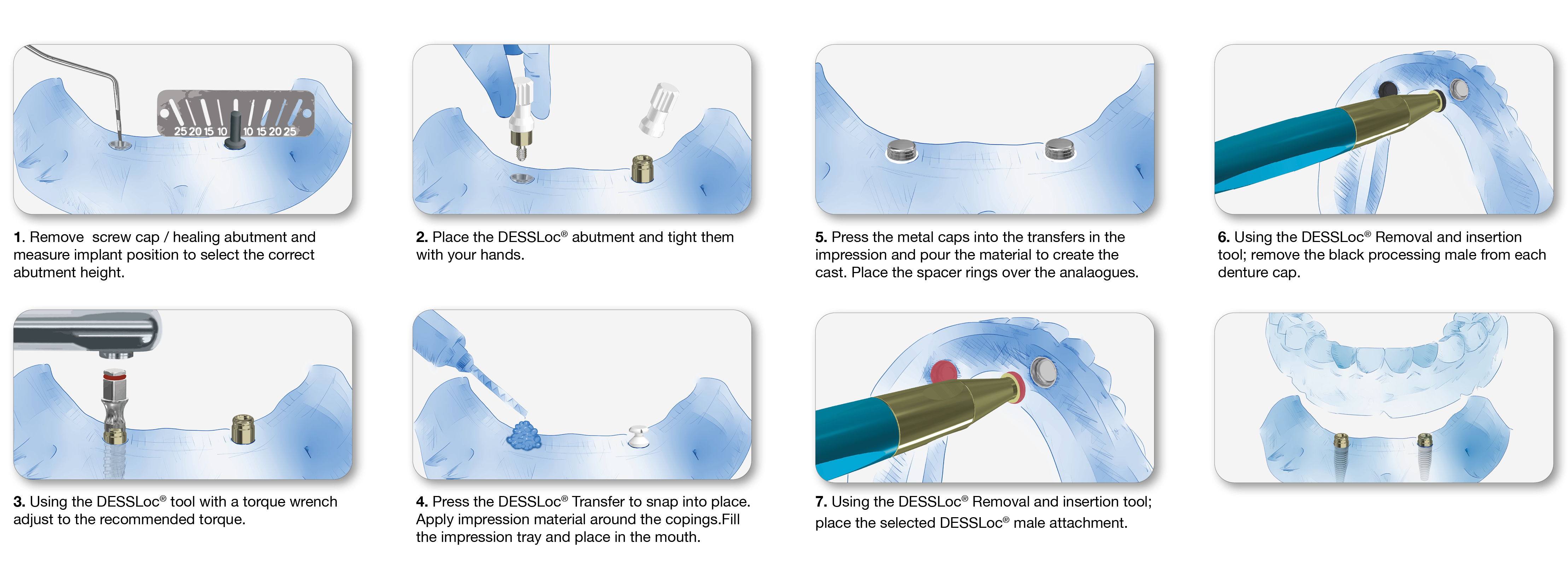

Instructions for use:

Compatibilities

Premilled Blanks

Create your project, Do It Yourself

The connection to the implant is one of the most important geometries in implant prosthetics and will allow for optimal biomechanical strength and longevity for the implant treatment. DESS® Pre-milled Blank system allows in-house customized milling of abutments and assures the DESS® quality and precision of the connection and screw seat.

The connection to the implant is one of the most important geometries in implant prosthetics and will allow for optimal biomechanical strength and longevity for the implant treatment. DESS® Pre-milled Blank system allows in-house customized milling of abutments and assures the DESS® quality and precision of the connection and screw seat.

Our pre-milled blanks are available in two materials and diameters: Titanium and Chrome-Cobalt alloy in 10mm & 14mm diameter. Chrome-cobalt premills offer several advantages over other materials on the market: no internal stress which preserves the custom design while offering less risk of breakage in the ceramic.

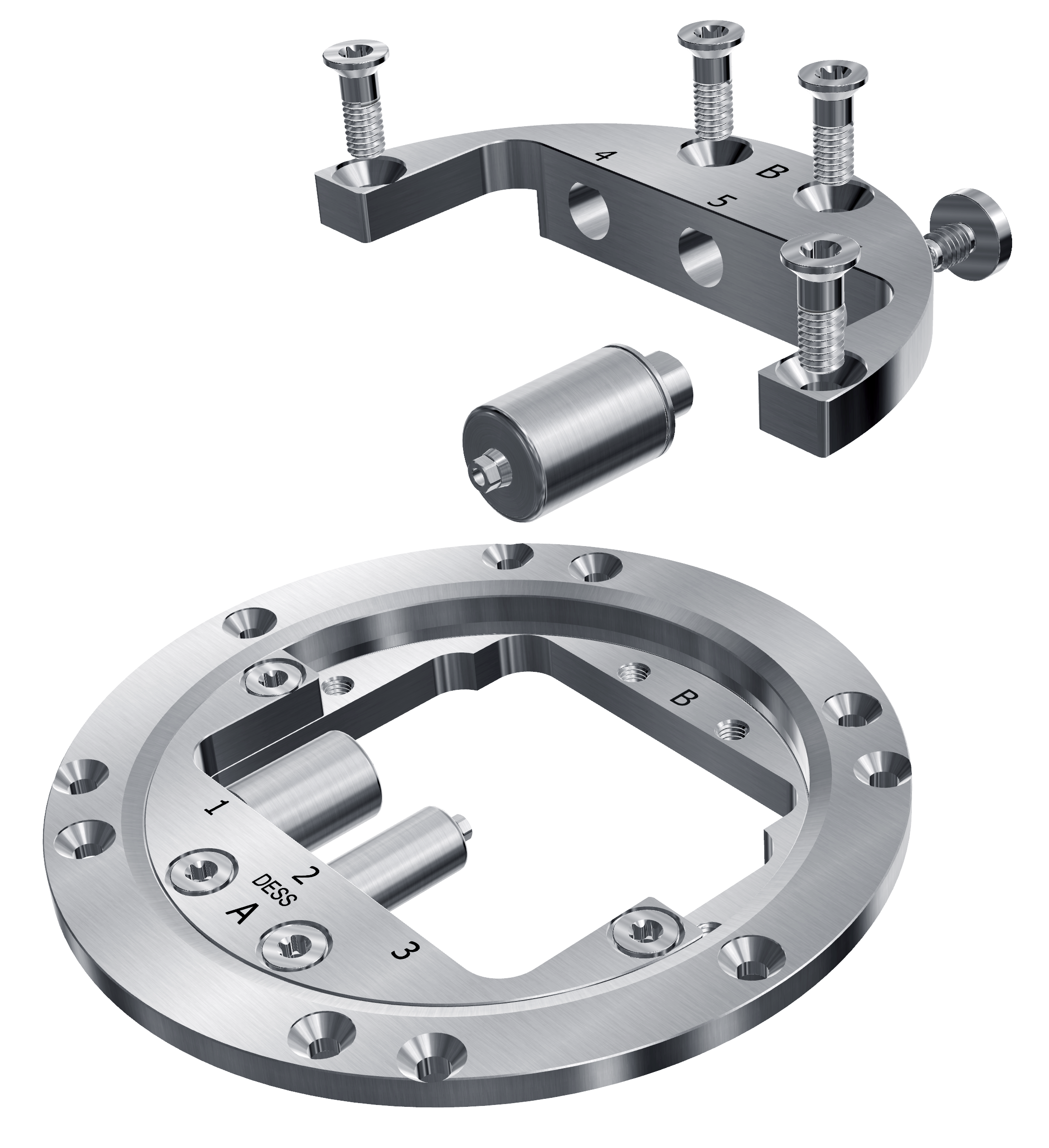

The Pre-milled Blank and Holder system is designed to save both time and cost to the laboratory. The holder provides a quick “screw-on” feature where the blanks are attached to the sub-holder outside the machine and placed in the main holder that remains in the machine.

The individual blanks are attached to the holder using a “pull down and lock” system that is time-saving and will assure maximum precision and stability during the milling process.

Milling blocks

DESS® milling blocks are available in two different heights: 20mm and 40mm and can be acquired in both Titanium and Chrome-Cobalt alloy materials. Together with the DESS® libraries you can create bars, bridges and multiples with the highest precision.

The blocks allow in-house milling to have total freedom in the creation of unique restorations, always maintaining the quality and precision that DESS® offers in all its products.

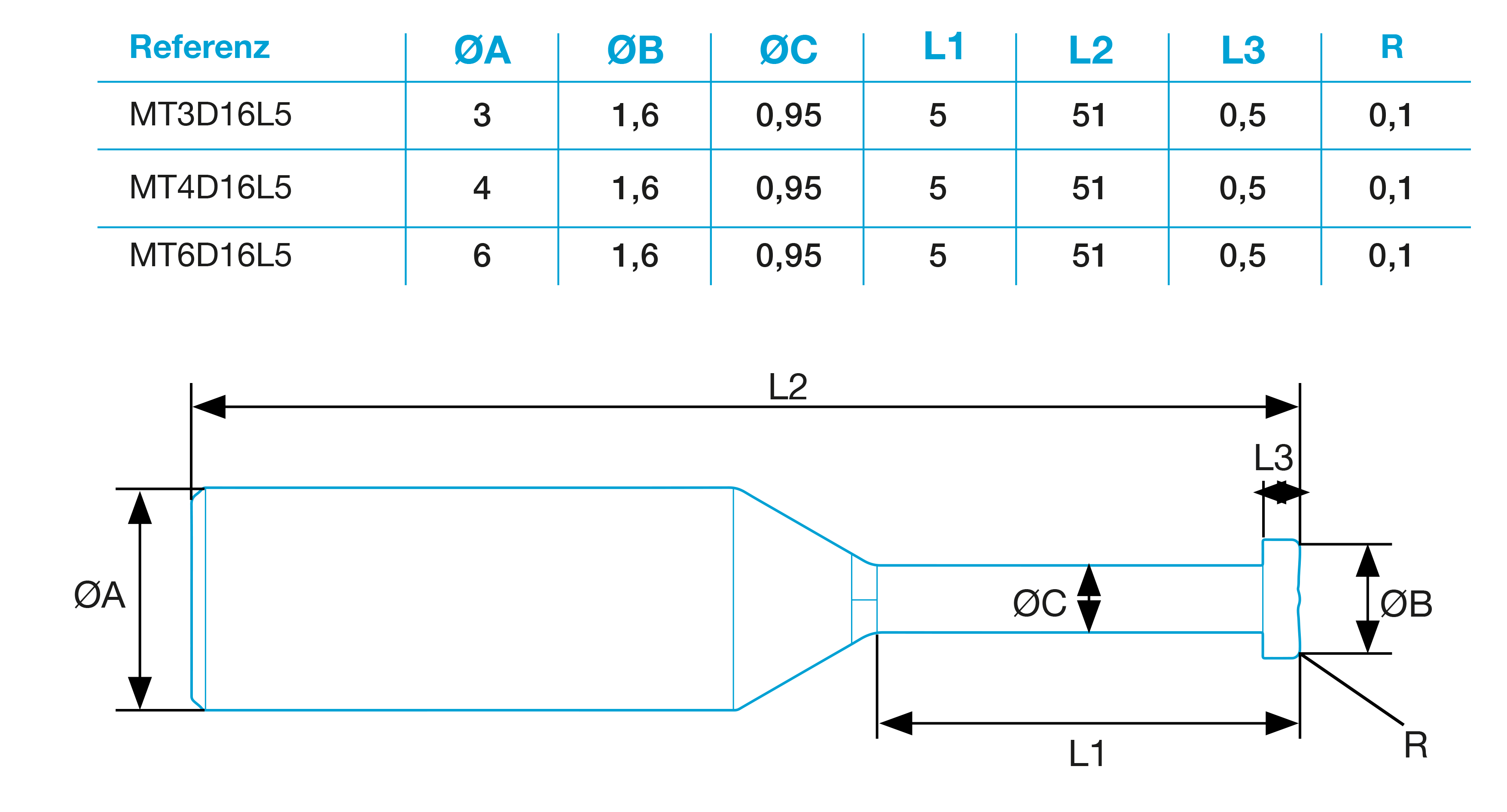

Milling Tool

Discover the new way to create bars, bridges and multiples autonomously thanks to our new milling tool. Take full control of your projects and create unique restorations with angled channels up to 25° with a single tool.

Thanks to this DIY (Do It Yourself) concept, you will be able to carry out your own project to ensure the required precision. The DESS® milling tool accurately replicates the DESS® AURUM screw platform. Get the right tool for every machine:

- VHF: 3mm

- Straumann: 3mm

- Imes-Icore: 3mm & 6mm

- ZirkonZahn: 3mm & 6mm

- Roland: 4mm

- Yenadent: 4mm & 6mm

Newsletter

Don't miss any novelty related to the company!

Contact Us

If you have any doubt, don't hesitate to contact us!